How to Use One Click Cleaner Properly

One click cleaner are made for cleaning 1.25 LC/MU , 2.5mm SC/FC/ST and MPO connectors. They are easy to carry, operate and simplifying cleaning procedure especially for the connectors or adapters located in patch panels, distribution hub, test equipment. They helps to remove the contamination from the endface to ensure optical performance.

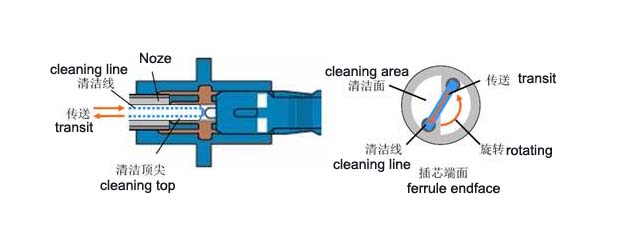

How the one click cleaner works? May see the following chart:

- Via push, mechanically starts the transit mode, rotates the cleaning tape to have the clean tissue tip reach and cleaning the end face effectively.

- The nose can protect the cleaning material and helping the cleaning tip reach the endface

Usage process:

–Remove the cap from the end of the cleaner

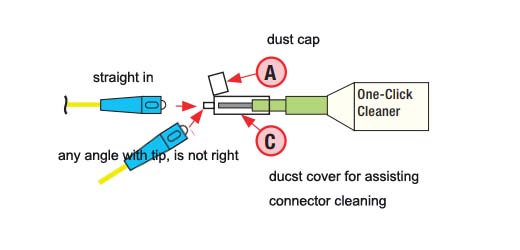

–Insert the end of cleaner into the connector to be cleaned , can extend the nose length if required, a dust cover cap part can be used for cleaning the connectors

–Press the cleaner forward until hear a “click”, then work done

Proper Usage:

The one click cleaner and connector endface is only 2.5mm or 1.25mm size, space is very limited. A Straight-IN insertion is required when access to all the connector or adapters to ensure effective result and long service life. If clean the connectors with angle between one click cleaner and connector may cause connector tip damage, scratching or might result in cleaner inoperable, shorten the cleaner life time.

Caution: Laser beam is harmful to eyes when view a live fiber.

We offer one click cleaners for different connectors including MTP/MPO one click cleaner, also other fiber cleaning material for fiber network installation or test , maintenance.