ADSS Fiber Optic Cable Failure Factors

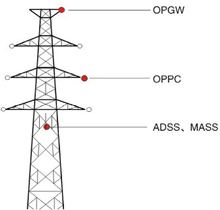

The ADSS fiber optic cable All-Dielectric Self-Supporting fiber cable is usually deployed along with the high voltage power line without outages since there is no conductive materials or components inside at an economical cost without extra building extra infrastructure.

The ADSS fiber optic cable is a version of self-supporting outdoor fiber cables, the mechanical characteristics such as RTS, MTA enable the cable to stand the weight of itself but also the impact from the environment including the UV reflection, wind, ice, especially strong electricity

The ADSS is installed 3m to 6m below the phase conductors which generate high electric fields to cause hardware corona, the conductor sag is sensitive to temperature which might have the dry-band arcing-caused failure. those two may damage and puncture the cable sheath to have water penetration and electricity activity aging and degrading the aramid. Cable failure or drop would happen after the flow of continuous erosion: If the cable is polluted or wet, dry band arcing happen, with the help of moisture, salt, fog, a pollution level might would be formed as conductive layer on the cable surface, as times flies, a more serious corona problem any raise.

How to avoid:

May use anti-electric trace sheath to reduce the strong electricity on the surface of the optical cable corrosion

Software and camera to be applied to detect the contamination and pollution distribution map to decide the optimal location for the ADSS fiber optic cable where has the less electrical field, ensure a safe distance from phase conductor and ground.

Fiber Zip Technology provides ADSS fiber optic cable with HDPE or AT dual jacket or single jacket for short span, media span, and long span application.