Fanout Kits Assembly Production Procedure

The breakout or fanout kits are often used for micro distribution cable or loose tube cable, they can be 0.9mm, 2.0mm, or 3.0mm to provide fiber protection and connector termination easily.

Fanout kits or break out kits are providing tubes to avoid exposing the bare fibers. They are considered to be applied when terminating fiber through a cable pass through plate, terminating fiber in a equipment rack.

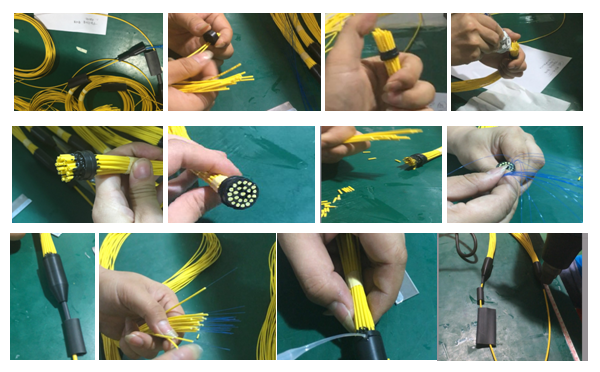

Following procedure is a part of the 24core mini fiber optic cable breakout/fanout 3.0mm production in factory for reference only :

- prepare the fiber cable in the required length, apply heat shrink tube on the fiber cable, might different size shrink tube required depends on the cable size to provide strain relief and limit fiber bending, jacket off the fanout length.

- prepare the empty tubes in required length, insert the empty tube to the kit out ports

- injection the glue to fix the empty tubes ensure it will fall out till glue dry

- cut the empty tube out-shape part(out part another side) to ensure the fiber can be insert the tube smoothly

- cut the out part tube evenly to prepare the fiber insertion, tide the fiber in array without twisted or crossed

- insert the fiber to the out-kit part, pull the fiber gently when all out to make sure no twist

- in and out kits connected, have some glue on the fanout kits part, shrink the tubes and prepare for next procedure

Different factory might have slight different technique or use different glue, no matter how it is critical to ensure the fiber not twisted in the kits or tubes for producing ribbon fanout kits or bundle breakout kits. Any twist leads to high attenuation or fiber break.

We carry a range of a fanout kits parts for different fiber cables or ready fanout kits for field installation and pre-terminated fanout /break out assemblies.